NIOSH VIBRATION

44 E&MJ; • MAY 2018 www.e-mj.com

www.Derrick.com

Derrick W56 Trash Screen removing carbon at 600 microns

Increase Gold Recovery, Reduce Costs, Improve

Performance & Efficiency, and Equipment Reliability

Derrick

®

offers solutions for fine screening in gold processing plants that effectively address

all of these objectives. Whether your application is cyclone overflow trash duty, tailings carbon

safety, in-tank interstage carbon retention, de-gritting, loaded carbon, carbon sizing, carbon

dewatering, gravity separation, or carbon column safety, Derrick has a proven solution for

you. Derrick screening machines – equipped with long-lasting, non-blinding Polyweb

®

urethane

surfaces – offer the highest screen throughput in the smallest available footprint.

D E R R I C K

®

U R E T H A N E S C R E E N S

®

Contact Derrick today to discover how you can increase efficiency and profits!

been clearly documented. Those levels

within the HGCZ indicate caution with

respect to potential health risks. The

exposure limit value (ELV) is the level

above which health risks are likely. Ta-

bles 1 and 2 display the EAVs and ELVs

in terms of aw and VDV.

Results

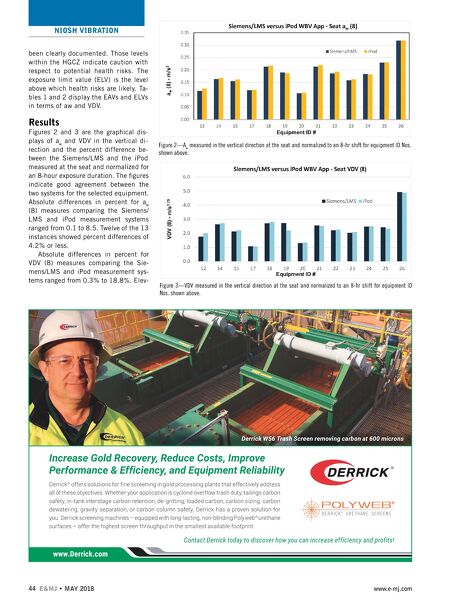

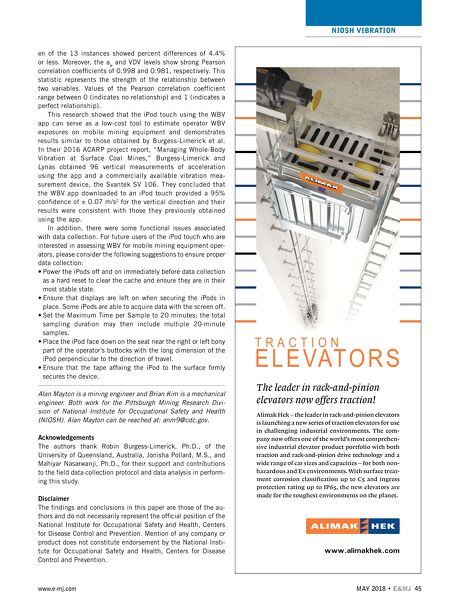

Figures 2 and 3 are the graphical dis-

plays of a

w

and VDV in the vertical di-

rection and the percent difference be-

tween the Siemens/LMS and the iPod

measured at the seat and normalized for

an 8-hour exposure duration. The figures

indicate good agreement between the

two systems for the selected equipment.

Absolute differences in percent for a

w

(8) measures comparing the Siemens/

LMS and iPod measurement systems

ranged from 0.1 to 8.5. Twelve of the 13

instances showed percent differences of

4.2% or less.

Absolute differences in percent for

VDV (8) measures comparing the Sie-

mens/LMS and iPod measurement sys-

tems ranged from 0.3% to 18.8%. Elev-

Figure 2—A

w

measured in the vertical direction at the seat and normalized to an 8-hr shift for equipment ID Nos.

shown above.

Figure 3—VDV measured in the vertical direction at the seat and normalized to an 8-hr shift for equipment ID

Nos. shown above.